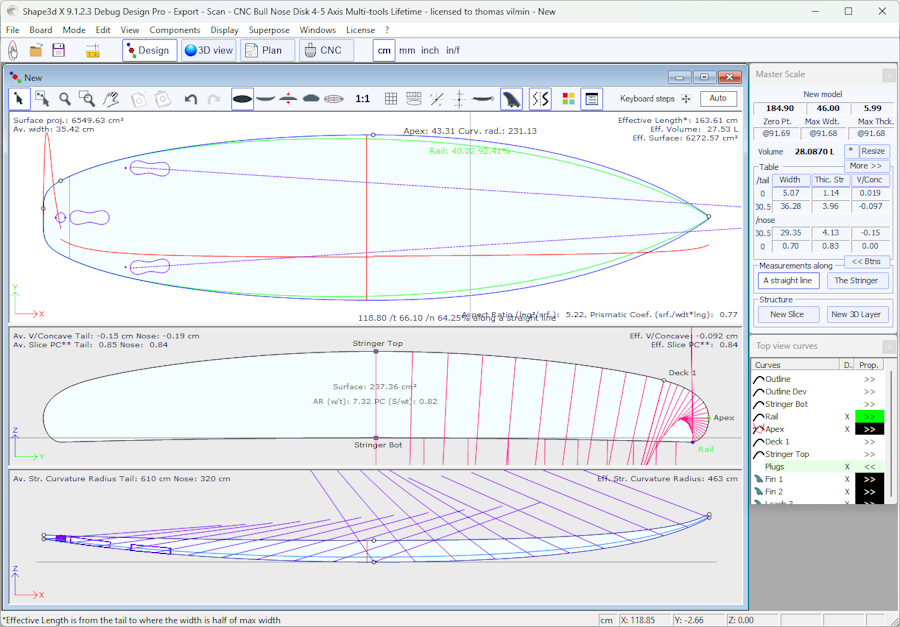

This will ensure there is enough foam for the machine to mill. *For top and bottom differentials, the ideal tolerance should be no less than 0.20" (5mm). X: How far from the tail of the board your mouse isĭiff Bot/ Diff Top: The distance between your actual design and the top of the blank outline that the will be milled by the CNC. Use your mouse to scan across the board, check these numbers: When your design is properly fitted in your blank, the outline of the blank will light up green.įrom there, you will want to check the differentials along the entire outline of the board. Once a cross profile fit has been established, Hold the Shift key down and use the arrow keys to anchor the back end of the board and move the nose up or down for a precise fit. Use your arrow keys or mouse to move the board into position. A red outline representing the selected blank will appear. For US Blanks, you will need to contact them at:Ĭhoose a blank file by clicking on the "Select" button. *To obtain blank files, please message us directly.

Open a design file and navigate the the Blank Fitting tab. To use the Blank Fitting tools (Available on the Up & Comer, Heavyweight, Premium Factory Plans.)

#Aku shaper installation manual how to#

Blank Fitting Startup guide on how to use the Blank Fitting tools Fitting your design into a blankĪfter a board has been designed, your CNC facility will need to match a blank with your shape.Īlternatively, the blank fitting options are good to use to determine the proper blank you will need for a handshape.

0 kommentar(er)

0 kommentar(er)